The 375 & 338 EnABELR Cartridges

Design, Technical Specifications and Performance

By: Bryan Litz

Mitch Fitzpatrick, shooting the 375 EnABELR in an ELR Competition

This paper provides details on the 375 and 338 caliber variants of the EnABELR cartridge (Engineered by Applied Ballistics for Extreme Long Range) developed by Applied Ballistics Weapons Division. There are 3 major sections to this paper. The first is Design Overview where the goals, constraints, and final design are explained. The second is Testing and Performance, where internal and external ballistic results are presented. The final section is Availability, where the development and availability of support components are detailed.

Figure 9. ABWD loaded 375 EnABELR ammo developed for the M30-TS weapon system

Design Overview

Figure 1. Example of overbore case

The concept of the EnABELR cartridge was born from experience with other large cartridges.

In the pursuit of ELR target engagement, high performance is always a goal, but some aspects of high performance can come at a cost. Consider the 375 Lethal Magnum, a cartridge developed by Mitchell Fitzpatrick in 2016, based on the 585 Hubble Express. This cartridge showed promise when Mitch won the 2016 King Of 2 Miles ELR competition with it, but over time, the practical limitations of the case became apparent. When you burn over 150 grains of powder, and propel a .375 caliber 400 grain bullet over 3200 fps, you generate incredible performance but it comes at the cost of high maintenance.

In this context, high maintenance means many things, and it’s important to understand the problems if a new cartridge is going to be designed to mitigate those problems. The internal ballistic problems of large cartridges correlate to the case volume to bore diameter ratio. In other words, how overbore the cartridge is. Chamber pressure and velocities can climb dramatically in just a few shots due to the extreme fouling conditions of such overbore cases. We’ve come to refer to this problem as velocity migration. Those with experience shooting large capacity wildcats are familiar with these problems, and the importance of restraining shot count, and frequent bore

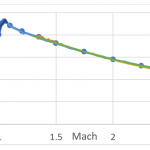

cleaning to stave off the effects of overbore cartridges and velocity migration (velocity migration and pressure increase go hand-in-hand). Figure 2 shows an example of severe velocity migration that was measured for a 375 Lethal Magnum. The muzzle velocity of nearly every shot was measured for the first 3 cleanings of the barrel. When you fit a line to the MV vs. shot count, the slope of that line indicates a velocity migration of between 0.9 fps/shot before the first cleaning, 0.7 fps/shot before the second cleaning, 0.4 fps/shot before the third cleaning, and 0.3 fps/shot before the fourth cleaning. With a velocity migration of 0.4 fps/shot, that means every 10 shots, your MV is increasing by 4 fps. After 50 shots, the MV has migrated up 20 fps. This level of velocity migration causes two big problems for the serious ELR shooter.

- The pressure increase that comes with the velocity migration leads to problems like stuck cases and safety concerns with ammo that produced moderate/safe pressure only 50 shots ago.

- Predicting what your MV will be with a high degree of accuracy is very important for ELR shooting. An error of only 8 fps represents a trajectory prediction error that exceeds the size of the target at 2 miles. It’s hard enough to load ammo a consistent enough MV for a string of shots, without compounding the predictability with velocity migration.

Severe Velocity Migration for the 375 Lethal Magnum

Figure 2. Velocity migration is a huge problem for the 375 Lethal Magnum, averaging 0.3 to 0.9 fps per shot between cleanings.

Clearly the design of a successful new cartridge for ELR shooting would have to fall somewhat below the capacity of the overbore cartridges that produce problematic velocity migration. To begin the search for a cartridge that would produce low velocity migration, we considered rounds proportioned for use in machine guns such as the 7.62x51mm NATO (308 Winchester) or the 5.56x45mm NATO (223 Remington) as a baseline, near zero velocity migration. Rounds like this are made to fire and cycle for thousands of rounds in automatic and semi-automatic rifles so there can’t be any substantial velocity migration or other high maintenance issues for them. So, somewhere between the machine gun rounds, and 375 Lethal Mag is where we wanted to be with the EnABELR.

In addition to the velocity migration issue, another design constraint was that the new cartridge had to be magazine feed-able with the best available bullets. This is a requirement imposed by the military application intents for the round.

The 9.5x77mm (375 CheyTac) round is a good candidate, and Applied Ballistics has experience with this round. Derek Rogers won the 2017 King of 2 Miles with this cartridge, and it has the performance to excel at Extreme Long Range, as well as manageable velocity migration which makes this cartridge a very attractive option for ELR. However, the problem with the 375 CheyTac is that, when loaded with the highest performance 375 caliber bullets (379 – 407 gr Berger Solids, and the 400 – 425 grain Cutting Edge Lazers) the round is not magazine feed-able in any action that’s sized for CheyTac cartridges.

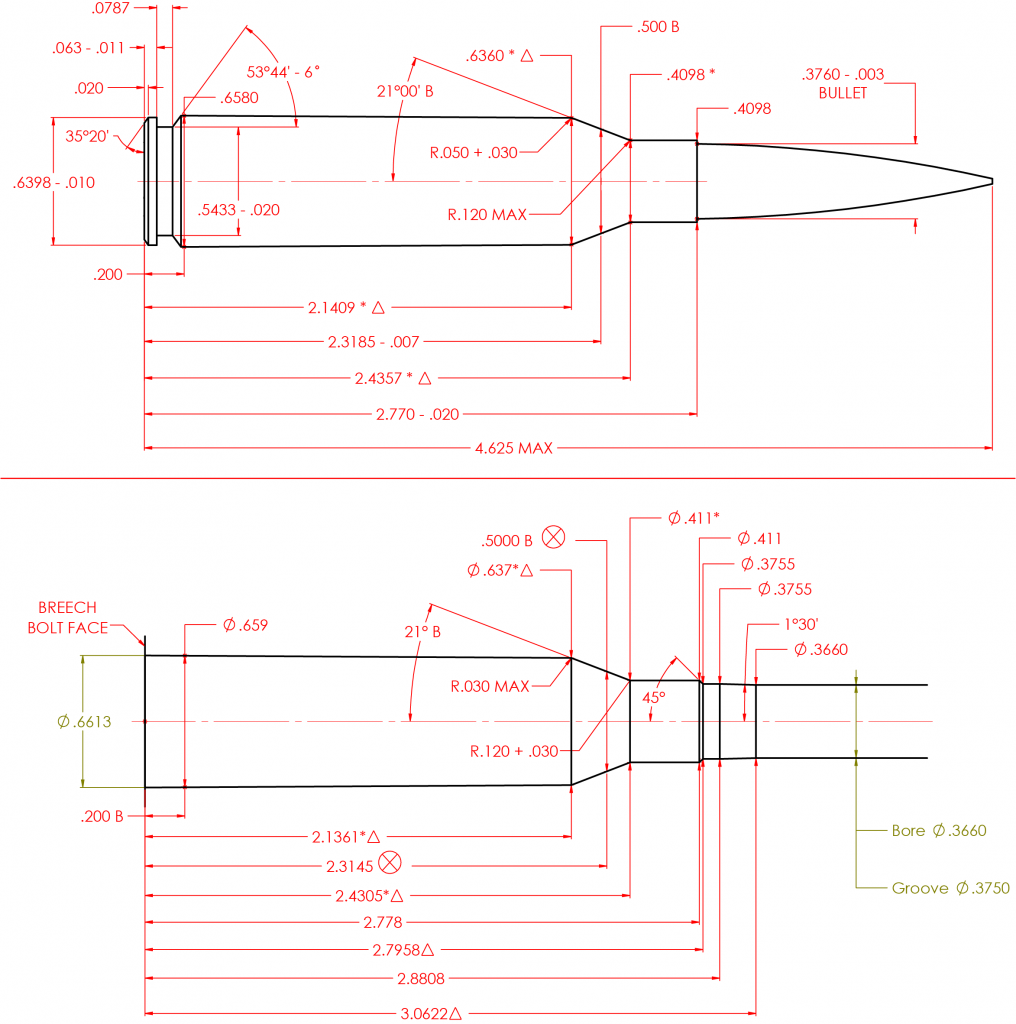

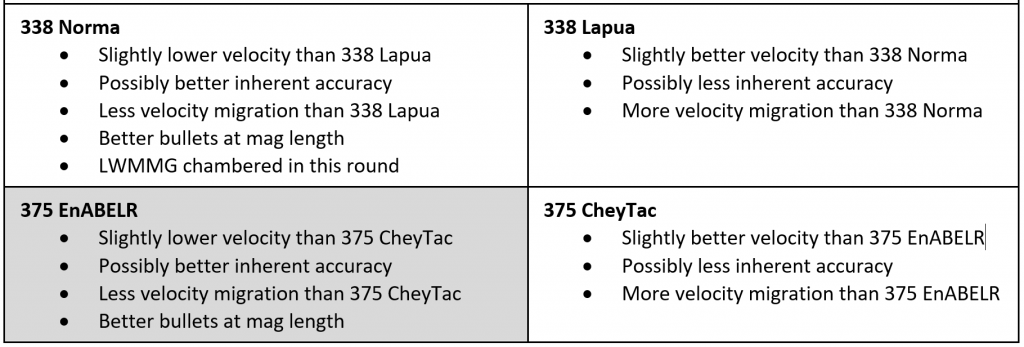

Knowing the 375 CheyTac produced substantial performance, and that it was just too long for magazine feeding, made it easy to converge on a design for the 375 EnABELR. We just had to make the case short enough to achieve magazine length with the desired bullets, while adding a little more diameter to keep the case capacity similar to the 375 CheyTac. The resulting basic shape is quite similar in proportions to the successful 338 Norma Magnum Cartridge which, interestingly, was selected as the cartridge for General Dynamics Lightweight Medium Machine Gun (LWMMG).

Obviously there’s a lot more to the technical process of designing a case, but the above considerations are the major factors in how we arrived at the basic design of the 375 EnABLER.

Table 1. The 375 EnABELR is like a scaled up 338 Norma, which is a cartridge known for inherent precision and reliable long term performance.

Figure 3. Peterson Cartridge Company made brass in both 338 and 375 EnABELR

Peterson Cartridge Company has been an eager and instrumental partner in the development of the EnABELR cartridge and the production of high quality brass. Peterson assisted in the internal design of the case including case wall and web thickness, etc. Between Petersons’ expertise in cartridge case production, and Applied Ballistics engineering of the overall cartridge design, the result is a cartridge that is optimized, within constraints, for its intended use.

Although the raw performance of the 375 EnABELR isn’t as high as some extreme wildcats like the 375 Lethal Mag, the benefits of balanced design far outweigh the drawbacks such as the requirement to form (wildcat) brass in many steps from a parent cartridge, for which brass is not easily available, velocity migration, short barrel life, single shot limitation, etc. Such limitations ultimately constrain how much shooting you can practically do with a round. Any experienced shooter knows the value of practice and familiarity with their rifle system and it’s very difficult to build up a confident base of experience with large overbore cartridges before you have to change the load, or the barrel burns out. By contrast, the low maintenance, shoot-all-day ease of cartridges like the 375 EnABELR allow a shooter to quickly converge on a work-able load (or purchase pre-assembled ammo), and focus on the challenges of shooting, without concerns of problems cropping up from the rifle system. As you’ll see in the following section, the 375 EnABELR is a proven success in this regard.

Most of the discussion so far has been on the 375 caliber variant of the EnABELR. During the course of development, we recognized that a natural extension of this cartridge is to neck it down to .338 caliber. This makes a cartridge that is very comparable to a scaled up 300 Norma Mag, which enjoys legendary status for being a high performance, inherently accurate cartridge design and was selected by SOCOM for the Advanced Sniper Rifle (http://soldiersystems.net/2018/05/07/ussocom-releases-advanced-sniper-rifle-solicitation/ ). In the same way that the 375 EnABELR is a big brother to the highly successful 338 Norma Mag, the 338 EnABELR is big brother to the highly successful, although more aggressively performing 300 Norma Mag.

Both cartridges have been developed, and factory Peterson Brass is available for both variants, although most of the testing and development you’ll see in the following section are centered around the 375 EnABELR due to its ability to launch the super high performance Berger Solid bullets, as well as being less-overbore than the 338 variant makes 375 a more attractive overall solution for the military and competition applications.

Figure 4. 338 EnABLER (left) loaded with Berger 300 gr Hybrid, 375 EnABELR (right) loaded with Berger 407 gr Solid.

Testing and Performance

Figure 5. Three 375 EnABELR cases, on their 8th firing, loaded with 407 grain solids during load development.

The 375 EnABELR has undergone an exhaustive battery of testing from many rifles, over the better part of a year before being released. The first prototype cases were received from Peterson Cartridge Company in March of 2018. AB Weapons Division already had rifles built, as well as reloading dies (FL sizing and bullet seating) so load development began immediately. Figure 5 shows a picture of some of the first pieces of 375 EnABELR brass on their 8th firing. Like other examples of Peterson Brass, the EnABELR cartridges have proven to be very durable, so long as they’re not exposed to overpressure firings, which can expand the case head too much to be resized all the way back down. More on this later.

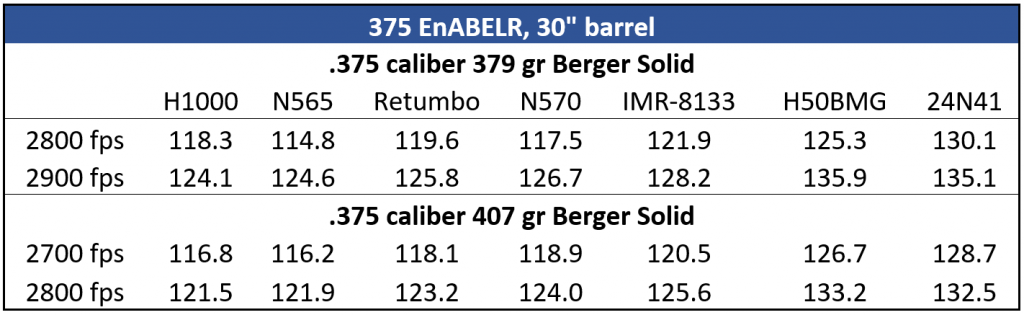

Table 1 below presents some basic load data for the 375 EnABELR. Considering the Berger .375 cal 379 and 407 grain Solid bullets were developed in conjunction with the EnABELR case, load data is provided to achieve certain landmark velocities with these bullets, for a range of suitable powders. It’s easy to remember that, in a 30” barrel (recommended) the 375 EnABELR can safely push the:

Berger 379 gr Solid to 2900 fps, and the

Berger 407 gr Solid to 2800 fps

These are conservative, baseline velocities. Higher velocities are possible but the above performance is safely achievable well within pressure limits of the cartridge.

Table 1. Load data for the 375 EnABELR

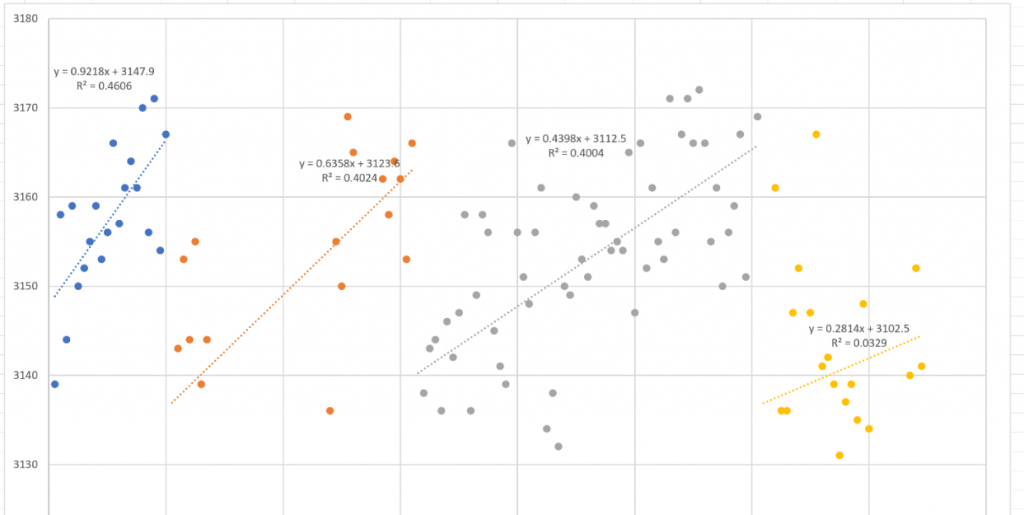

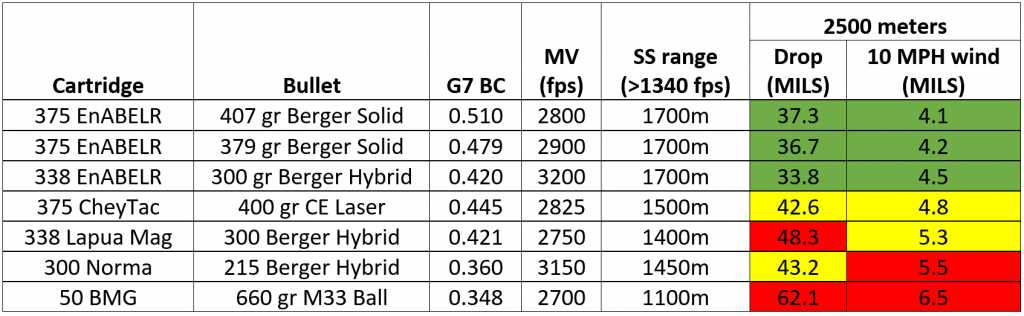

After establishing the load data, and potential velocities that can be responsibly/safely achieved with the EnABELR cartridges, it’s interesting to consider a performance comparison with other cartridge/bullet combinations used in ELR shooting.

Ballistic Performance Comparison

Table 2. Basic ballistic performance comparison between the EnABELR and other rounds commonly used in ELR.

Note the performance of the 375 EnABELR is driven by the high BC Berger Solid bullets. If the 375 CheyTac were loaded with the same bullets, the performance would be about the same. Performance of the 338 EnABELR is driven by the high velocity that’s possible with the 300 grain Berger Hybrid. The comparison of 375 options in Table 2 is showing the difference in bullet performance between the benchmark 400 grain Cutting Edge Lazer and the Berger Solid bullets more so than the cartridge comparison. Nevertheless, it’s clear to see that the EnABELR, when loaded with the Berger Solid Bullets, outperforms everything else that’s typically used in ELR shooting including the 50 BMG loaded with M33 Ball ammo. Again, there are higher performance options for 50 cal, and this chart is showing what’s considered standard performance for various classes of ELR cartridges.

The metrics shown in Table 2 are those most commonly associated with ELR shooting:

- G7 BC and MV are the properties of the round.

- Supersonic (SS) range is of interest because projectiles are most predictable out to the range where the bullets slow to transonic flight. Then it becomes a question of how well the bullets transition. The Berger Solid bullets have proven to transition well, and fly with predictable trajectories well beyond their supersonic range, which is 100’s of meters further than most bullets.

- Drop is of interest because often times ELR rifle systems are limited by how much elevation they can dial. Typical scopes used for ELR will have 100 MOA, or 30 MILS of elevation available before the shooter has to augment this with a holding reticle, an adjustable scope base, or a periscope, such as the TacomHQ Charlie.

- Wind deflection is a highly decisive variable in a shooters ability to hit targets at long range. Minimizing wind deflection is one of the primary measures of merit for ELR performance, and the 375 EnABELR loaded with Berger Solid bullets minimizes wind deflection better than any other conventional option.

It’s good to consider the performance when selecting a cartridge for ELR, but the proof is in the field testing. You want a cartridge that’s not going to give you problems, or have some unforeseen issue. The Applied Ballistics ELR Team spent the entire 2018 shooting season field testing the EnABELR cartridge in many rifles and matches. We had 4 competition rifles, plus 4 test rifles chambered in 375 EnABELR with various twist and length barrels. In all those rifles, firing all the different bullets in ballistic testing and competition, we didn’t experience any issues related to excessive velocity migration or unexplained anomalies of any kind. The cartridge just flat out shoots! Here’s a partial listing of the accomplishments we achieved with the EnABELR during its first year of testing.

Received initial quantities of prototype brass and began load development.

Doppler Radar testing of the 375 EnABELR and Berger Solid Bullets was conducted at 300 and 1000 yards.

Spin drift testing at 2200 yards involving 4 different 375 EnABLER barrels in 2 different twists, 20 rounds of 6 different bullets each, which all performed with no issues at distance. Especially predictable and consistent performance was observed with the Berger Solids at this distance.

Radar testing at both 2200 and 2400 yards was conducted.

The Applied Ballistics ELR Team competed in the Worlds Longest Shot Challenge where Chris Palka (AB Team member) won the event using a 375 EnABELR loaded with 379 grain Berger Solid bullets. The second place shooter in that match was Paul Philips who was shooting the 407 grain Berger Solids (although loaded in a 375 CheyTac rifle, a pre-EnABELR build).

Chase Stroud continues to push the limits of the EnABELR cartridge in his AB Weapons Division built M30TS shooting 407 gr bullets:

• 8” group at 1760 yards

• 4/4 Impacts (3’ square) at 2150 yards

• 3/5 impacts at 2750

• Cold bore impact at 2200 yards during World Record Attempt

• Second place in the NRA ELR Nationals at Camp Atterbury, IN.

• Experiments with subsonic performance, achieving consistent MV ~1080 fps and ½ MOA group at 100 yards with Berger 407’s in 7 twist ABWD built M30TS.

As a test of the new Berger Solid bullets, Chase Stroud loaded some 407’s in his 375 CheyTac and with no load development, got a zero at 100 yards, confirmed at 1000 yards, and hit the 2 mile target (3 foot square) within the next 5 shots. This is an encouraging display of the ease of use offered by the Berger Solid bullet design.

Load development and testing begins with the 338 EnABELR using both Berger 300 gr OTM’s and a prototype 301 grain Solid bullet.

Brass prototyping ends, and we invest in production tooling with Peterson Cartridge company to produce mass quantities of the EnABELR brass in both 338 and 375 caliber variants.

Further results with the same shooter and EnABELR rifle but with 379 gr Berger Solids:

• Sub MOA group at 3562 yards.

• Cold bore head shot on IPSC at 1000 yards

• 15/30 impacts on a 3’ square at 2400 yards including first 4 (cold bore) shots.

• Cold bore impact at 2400 yards

• FIRST KILL with the 375 EnABELR: 1002 yard first round head shot on a doe in TX.

AB ELR Team shooter Chris Palka placed 3rd in the Georgia ELR Match shooting the 375 EnABELR and 379 grain Berger Solids.

Mitch Fitzpatrick refines 338 EnABELR load with Berger 300 grain Hybrids and demonstrates long term, sustainable accuracy with AB Weapons Division built M30TS. The 375 EnABELR is selected for Phase 2 of the Extreme Sniper Strike Operations (ESSO) weapon system, a government funded project to develop an ELR sniper weapon system.

Based on all of the testing that’s been done to date, it’s fair to say that the 375 and 338 EnABELR cartridge are being introduced to the public as very well tested and refined cartridges. The performance is exceptionally high for a round you can shoot all day with little worry of fouling or over-pressure issues. The size and magazine feeding capability provide the shooter with a truly versatile and practical solution to hitting small targets at extreme distances without the hassle and challenges of other, more overbore ELR options.

Availability

Figure 6. ABWD Reloading dies

As of February 2019, all components required to get up and running with the 375 EnABELR are being offered by Applied Ballistics Weapons Division. Unlike some wildcat cartridge inventors who choose to keep their designs secret and sole source everything related to their creation, ABWD has chosen to standardize and proliferate the EnABELR cartridge designs, even going as far as offering chambering reamers for other gunsmiths to build EnABELR rifles. We feel that the best chance for long term success of the EnABELR is to support the community by providing the information and tools, so the results can be standardized across the board, and shooters are more likely to have a positive experience regardless of who’s building the rifle.

In addition to reamers, ABWD is offering high quality reloading die sets in both 375 and 338 EnABELR. The full-length resizing die uses a neck bushing which creates about 0.003” neck tension with the Peterson brass, which our testing has shown to be optimal with the EnABELR cases. The bullet seating die is micrometer adjustable in 0.001” increments for accurate and precise seating depth adjustments. The dies thread into any 1.25”-12 press. The EnABELR case works with a #47 shell holder.

One of the big problems faced by ELR shooters is finding a reliable supply of quality ammo components. That’s why AB Weapons Division and Peterson Brass Company have made the commitment and the investment in large quantity production runs of brass, so that shooters can have a reliable supply of quality brass to feed their EnABELR rifles.

No need to worry about obtaining custom die sets to neck down a parent cartridge into a suitable wildcat to enjoy success in ELR shooting. Applied Ballistics is mainstreaming finished components to the end user, exactly as they need to be so you can assemble ammunition and begin shooting just as easily as you do with a 308 Winchester. There’s no reason why loading ammo for ELR shooting has to be more complicated than conventional cartridges, and ABWD has made it easy to get into this fully developed cartridge with minimal hassle.

Figure 7. Peterson Brass

Of course, for those who are ready to take the plunge, ABWD offers complete rifle systems chambered in 338 and 375 EnABELR for both tactical and competition uses. We have components in stock to build you a complete rifle system on a Cadex Chassis, an M30 – Tactical System (M30-TS), or if you don’t need the versatility of a tactical weapon system, and are more interested in a target shooting or competition rig, we can build you an M30 – Competition System (M30-CS).

Figure 8. M30-TS

Both of these systems can come equipped with a NF ATACR 5-25 scope in various configurations. Furthermore, all of the ABWD systems can be purchased with ammunition that was developed in that specific rifle, and tested under doppler radar, with a Custom Drag Model (CDM) of that specific combination loaded onto an Applied Ballistics device of your choice.

For customers who order complete M30 systems, we can provide ammunition loaded with the Berger 379 gr or 407 gr Solid bullets as well.

There’s simply no more complete system available on the market. The unique strength of Applied Ballistics Weapons Division is offering systems designed from the ground up, optimized for a specific purpose, assembled by experts who shoot and win with the same systems. With Doppler radar and a full time Ballistics Lab supporting all efforts, AB Weapons Division is proud to offer the EnABELR cartridge, rifles, and support equipment required to enable you to achieve success at Extreme Long Range Shooting!

Figure 9. ABWD loaded 375 EnABELR ammo developed for the M30-TS weapon system